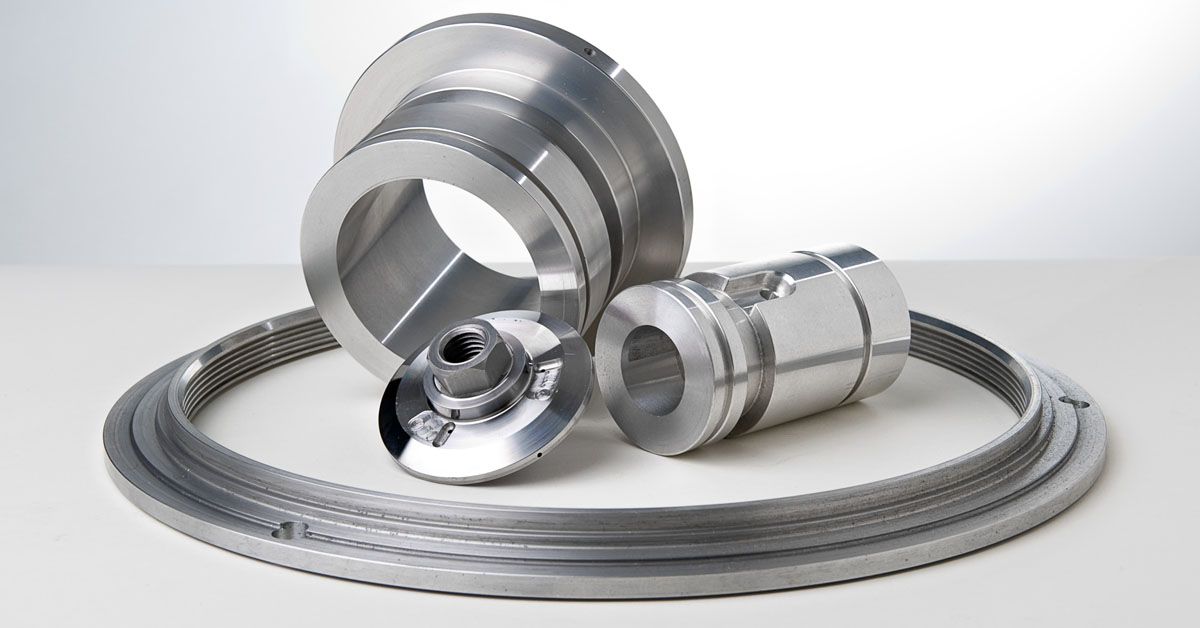

Wheeler manufactures and repairs babbitt and bronze bearings for any industrial requirement.

For close to a century, Wheeler, an ISO 9001-2008 Certified Supplier, has been helping industry solve their bearing needs by providing precision CNC machining, rebabbitting services and design assistance. Aligning with industry giants General Electric Support Services and Glyco Metall Werke, Wheeler is a leader in supplying bearings, oil rings and seals to the electric motor, power generation, compressor, pump and machine tool industries. For over 75 years Wheeler has supplied bronze and babbitt sleeve bearings to GE, Westinghouse, Allis-Chalmers, Siemens, Reliance, Baldor and many other electric motor manufacturers.

We maintain the largest inventory in the world of replacement bearings and oil lubrication rings for sleeve type electric motors for any urgent or planned requirement.

Since 1919, Wheeler Bearing Company has led the field in the manufacture and repair of industrial babbitt, bronze and aluminum bearings, oil rings, deflectors and labyrinth seals.

- Cylindrical, lobed and tilting-pad journal bearings

- Plain or sleeve bushings and liners

- Thrust bearings, plates, washers

- Precision 5-axis machining, EDM services, complete rebabbitting of bearings and pads

- Industrial & custom engineering

You have the right to expect world-class precision manufacturing, quick rebabbitting services, and innovative design & modeling assistance. We believe we can provide it. Our staff includes professional and graduate engineers with extensive experience in rotor dynamics, critical speed mapping, finite element analysis, hydrodynamic and hydrostatic bearing design and 3D CAD modeling.

Our 17,000 square foot manufacturing site houses an in-house babbitt and aluminum foundry, cutting-edge technology and equipment, 20,000+ OEM drawings, and provides you with access to the largest inventory of replacement motor parts in the world. We are committed to Lean Manufacturing principles and sustainable manufacturing practices. We provide ROHS-compliant bearings and seals from A850.0 aluminum and all our materials are sourced in accordance with Conflict Minerals guidelines.

You deserve outstanding customer service and knowledgeable staff that have the solutions to your problems. At Wheeler, our employees are our best asset. Deal with long-term technicians who take a justifiable pride in their work and have the expertise to tackle any problem you throw at them.

Work with a design team that rises to the challenge whether you want expert verification of your own design or are looking for a totally new application. You can expect the members of our customer support staff to be knowledgeable and friendly. At Wheeler you get a person, not a recording. Contact Us so we can put our work ethic to work for you.