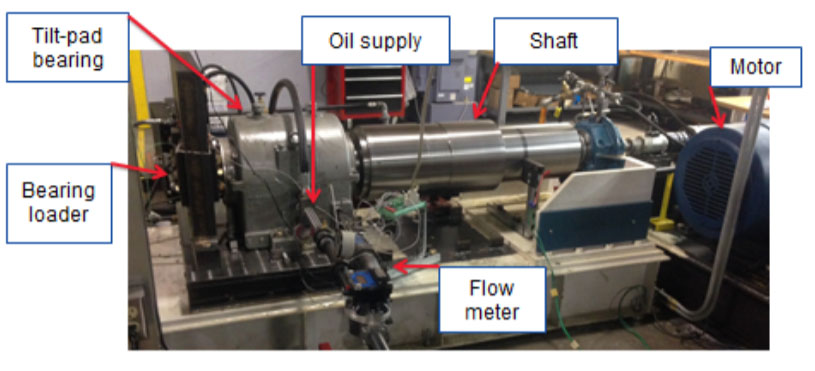

A test rig design was developed that would enable testing of journal bearings at equivalent peripheral speeds and unit loadings comparable to those found in large gas turbine applications. The design criteria of the rig required it to attain speeds of over 16,500 sfm and impose loads of over 10,000 pounds.

The test rig rotor is driven by a 100 HP two pole induction motor that is controlled by an adjustable frequency inverter. A special carbon fiber cogged belt is used on a set of pulleys having a radius ratio of 3.54 to 1.

A light weight high speed coupling is used between the high speed spindle and the test rig rotor. The motor drives a high speed spindle that is supported on angular contact bearings. A rolling element bearing is also used on the input end of the test shaft to minimize the horsepower absorbed by the test rotor. The input end angular contact bearing is supported inside a squeeze film damper to ensure smooth rotor dynamic performance throughout the entire operating range.

The test end of the system uses a cast housing that accepts a 6 inch diameter journal bearing. The test rig shaft extends beyond the bearing housing where a duplex pair of angular contact bearings are installed on the shaft. These bearing fit into a housing that is free to rotate and move in all directions about 0.005 inches. The housing for the angular contact bearings is fitted with a hydraulic cylinder so that a downward force can be applied to the outboard bearing housing during the rotor operation. The test rig uses three separate oil systems so that the oil lubrication to the test bearing is not shared in any way with the shaft system lube systems.

The above described test rig has been built and successfully operated under full speed and full load conditions. A computerized data acquisition system measures and records the inlet, outlet and various other lube system temperatures in addition to the ambient temperature. Tests have been conducted using various oils to measure the horsepower loss associated with each lubricant. Mineral and synthetic oil have been tested using the above described test rig.

Contact Wheeler Industries, Inc. to learn more about our full speed, full load journal bearing testing capabilities.